The methods of manufacturing and product design have evolved as we've progressed from revolutionary inventions such as the light bulb to telecommunications phones, the age of the radio, and televisions. Behind the advances in modern mold making, in the field of mold making supplies, the driving forces are Computers, the internet, sustainable power, and everything.

Mold making

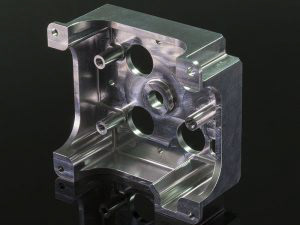

Mold making is a process that prepares injection molds which are then used to produce precision plastic parts. It is one of the most significant product investments so it becomes necessary that the molds are made with a great deal of accuracy. To ensure that parts can be mass-produced with repeatable accuracy modern plastic injection mold making requires extreme precision.

Perfection is also needed in the creation of the tools that are used to manufacture, hold, or test products during production. Variables that can have an impact on the cost of the plastic injection mold include:

The complexity of the Part

Greater the degree of complexity of the desired part, the higher the cost of the mold required. The reason behind the positive relationship is due to the mold design that needs to accommodate all of the part design requirements, including surface texture and tolerance.

Number of Cavities

The number of cavities impacts the time, labor, and costs required to manufacture a mold regarding mold production and mold supplier do face issues. Generally, to lower resource investment, fewer cavities in a mold design are translated, while more cavities demand higher resource investment. To achieve the highest production efficiency at the best possible value experienced mold makers should be able to optimize the number of cavities.

The complexity of the Part

Greater the degree of complexity of the desired part, the higher the cost of the mold required. The reason behind the positive relationship is due to the mold design that needs to accommodate all of the part design requirements, including surface texture and tolerance.

Number of Cavities

The number of cavities impacts the time, labor, and costs required to manufacture a mold regarding mold production and mold supplier do face issues. Generally, to lower resource investment, fewer cavities in a mold design are translated, while more cavities demand higher resource investment. To achieve the highest production efficiency at the best possible value experienced mold makers should be able to optimize the number of cavities.

Mold Base

The mold base is made of steel and is designed in such a way that it can hold the mold cavities, inserts, and other components together. The cost of making a mold base varies depending on the type of steel used, customizations added, and the size of the mold.

Core Metal

The material chosen for a mold is significantly influenced by the expected length of a production operation. For injection mold making supplies when you choose a material then it becomes important to consider whether to invest in an expensive but long-lasting mold it is more cost-effective or uses a cheaper but less durable mold and replace it when worn.

Know What Has Changed

During the 18th and 19th century’s plastic injection molding first gained prominence. Toolmakers had to do most everything by hand with the Industrial Revolution at its peak. A significant time commitment is required for heat treating, sharpening, forming tools, machining metal, and drilling out the design. Conformity problems often arose due to the uniqueness of anything made by human hands and no two molds were precisely the same.

CNC Milling Machines

CNC milling machines have contributed to the change from manual to computer-assisted machining. Initially, it took the form of 2D Bridgeport milling machines integrated with CNC attachments. They changed the way manufacturers worked on parts once they were introduced, as with minimal manual oversight they allowed for greater precision and faster processing speeds.

3E Rapid Prototyping Limited

Head Office & Factory 1:

No. 18-1 Gangkou Avenue, GangKou Town, Zhongshan, Guangdong, China 528447

No. 18-1 Gangkou Avenue, GangKou Town, Zhongshan, Guangdong, China 528447

Factory 2:

No. 9, QunFu industry Rd, GangKou Town, Zhongshan, Guangdong, China 528447

No. 9, QunFu industry Rd, GangKou Town, Zhongshan, Guangdong, China 528447

Phone: +8676088411100

Fax: +8676088411110

Email: info@3erp.com

Fax: +8676088411110

Email: info@3erp.com